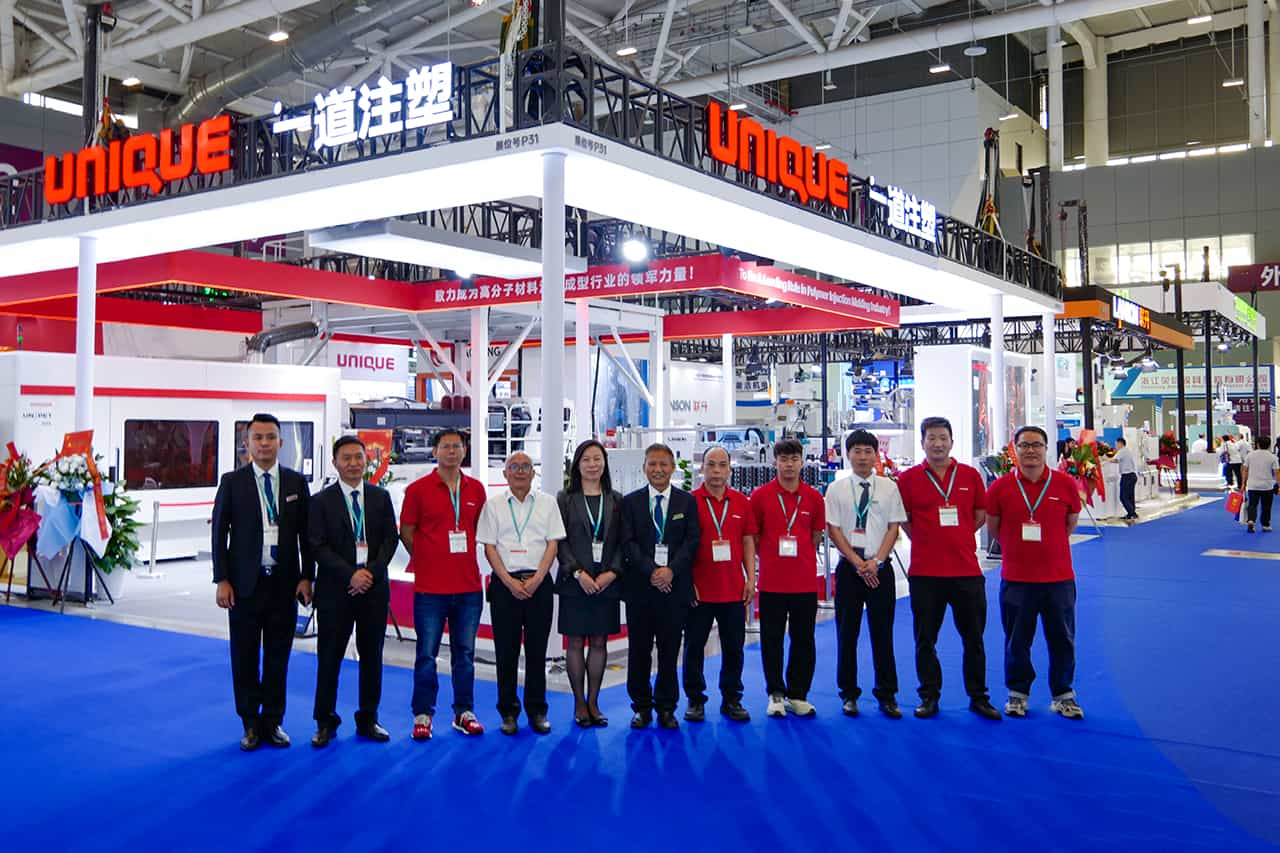

[Chinaplas 2025 Concludes Successfully] UNIQUE Leads PET Injection Molding with Innovative Technology, Charting a New Industry Landscape with Global Clients

Four Days of Grandeur, 3,000 In-Depth Technical Exchanges

The 2025 International Rubber and Plastics Exhibition (Shenzhen) concluded perfectly. Unique Injection Molding Systems Co., Ltd. (UNIQUE), under the theme "Smart Manufacturing for the Future," presented a visual feast of PET injection molding technology at Booth P31. The combined demonstration of the 300L High-Speed PET Preform Injection System and the 128-Cavity Mold System not only secured in-depth discussions with clients from 45 countries but also redefined industry standards with live performance data.

I. Core Technologies Defining New Industry Benchmarks

300L High-Speed PET Preform Injection System:

1. Millimeter-Precision Drive: Utilizes the golden combination of Servo Motor + MOOG Controller, achieving positioning accuracy within 0.1µm. Live demo showed synchronized production consistency reaching 99.9%.

2. Ultra-Stable Production Cycle: Requires only 1.2 seconds for mold open/close dry cycle time. 6-hour continuous live production provided clients with "zero-variation" production assurance.

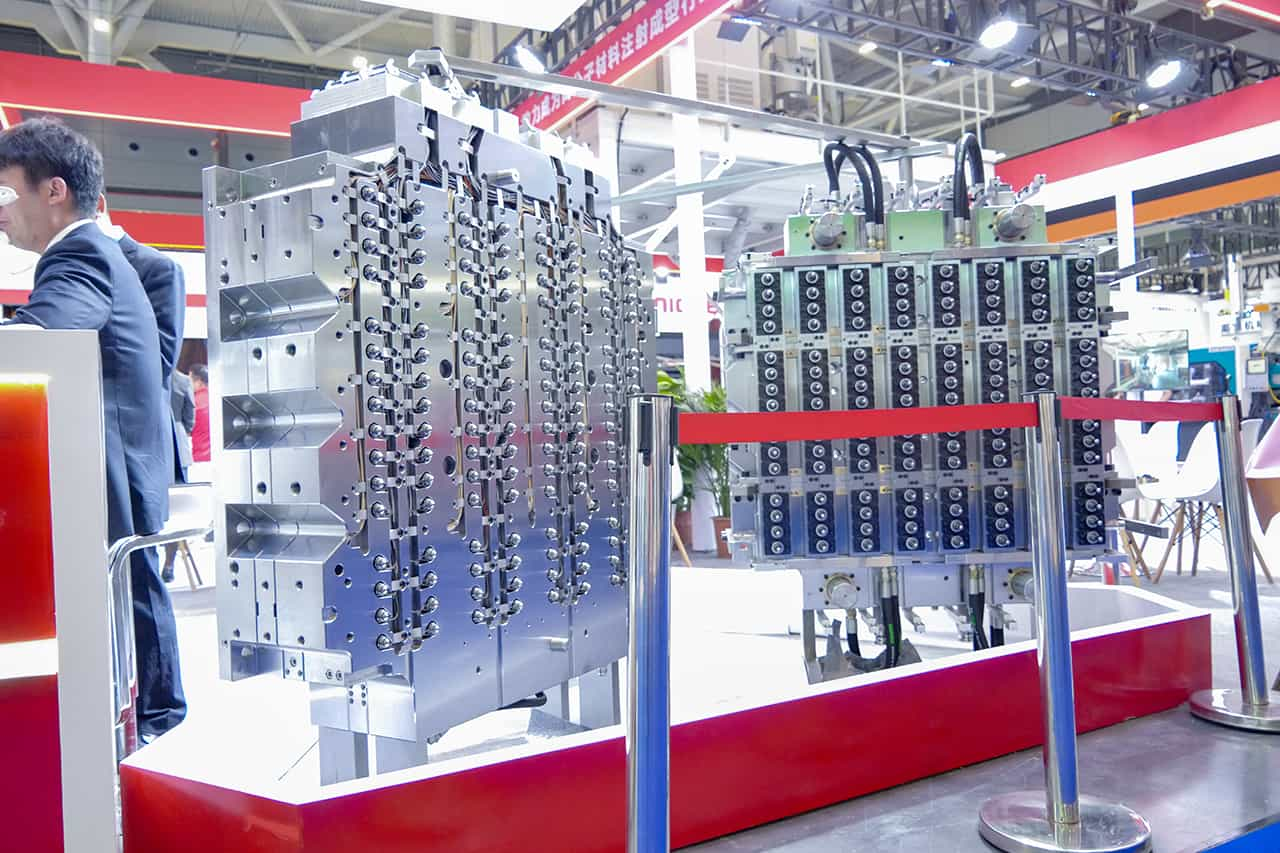

II. 128-Cavity Mold System Technological Breakthrough:

1. German Precision Hot Runner Technology: Delivers precise temperature control. Features the proprietary Unipet Quick Mold Change System, compatible with mainstream brand equipment.

2. Intelligent Cooling & Hot Runner Design: Utilizes parallel cooling circuit design optimized based on fluid dynamics. Suitable for multiple solutions, delivering excellent cooling efficiency.

III. Two Decades of Focus: Becoming a Comprehensive PET Preform Injection Solution Expert

Since establishing roots in Guangzhou in 2005, UNIQUE has evolved into a full-solution service provider in the PET injection molding field. We offer:

1. Turnkey Projects: From preform design to complete production line implementation.

2. Comprehensive Packaging Solutions: Covering all categories including water, dairy products, condiments, edible oils, and more.

3. Full Equipment Lifecycle Services: Technical upgrades | Mold refurbishment | Smart retrofitting.

"The end of the show marks the beginning of our service. We've already secured 30% pre-orders for next year right at our booth." — Wang Jianjun, General Manager, UNIQUE.

2026, Let's Create More Brilliance Together!

Make Precision Standard. Let Innovation Drive the Future. UNIQUE looks forward to meeting you at the next Chinaplas to jointly explore the limitless possibilities of PET injection molding technology.